23

Oct

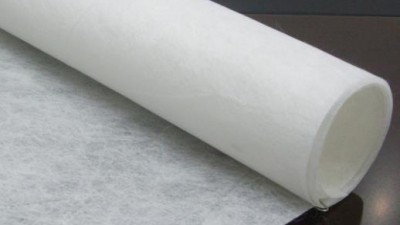

About five percent of all carpets are produced in a needlefelt procedure. Layers of non-woven fleece made of staple fibers are needle-punched and compressed on a tuck presser. The carpet is given additional stability with a backing material or using special chemical or thermal bonding. Good-value, tough needlefelt is particularly durable. It can withstand extreme temperatures, is extremely scuff-resistant and is even resistant to contact with chemicals.

| Product Code: | NP/TB/PTB |

| Grammage: | 100 g/m² – 900 g/m² |

| Application: | Automotive Carpetting & Building Flooring |

| Keywords: | Carpet, Felt, Automotive, Commercial |

Non woven carpets are manufactured by a different process compared to Tufting and Weaving. Non woven carpets are made from Polypropylene Fibres. The fibres are formed into a web by Needle punching and then thermally bonded to form the carpet. They are most commonly used for Automative applications, for short period usages like exhibition halls and foot-mats, etc.